Choosing the Right Safety Boots for the Job: The Ultimate Guide

Are your work boots falling apart way too soon?

Do you feel like you’re buying a new pair every year, or even every few months? It’s a frustrating and expensive problem. But what if the problem isn’t the boot? What if it’s that you’re accidentally using the wrong tool for the job?

Making sure you are choosing the right safety boots for the job is the single most important step to ensure your feet are protected and your investment lasts. Using a lightweight boot meant for a warehouse on a heavy construction site is like taking a normal car on a rocky mountain road—it’s going to break down.

This guide will walk you through everything you need to know. We will break down the common jobs in Malaysia, explain the specific dangers of each, and show you exactly which features you need in your protective footwear. By the end, you will be able to confidently select a pair of work boots that not only keep you safe but also last a long, long time.

Why Matching Your Work Boots to Your Job is So Important

Think of your safety shoes as a piece of essential equipment, just like a power tool or a piece of machinery. You wouldn't use a small drill for a big job, and you shouldn't use a light boot for a heavy one.

When a boot is used in an environment it wasn't designed for, it fails. The leather gets torn, the sole separates, and the safety features get worn down. This not only wastes your money but, more importantly, it puts you at serious risk of injury.

Every single job has its own unique set of hazards. A chef faces slippery floors, while a construction worker faces falling objects. A logistic worker needs something light for walking all day, while a mechanic needs something that can resist oil. Choosing the right boot means you are prepared for the specific dangers you face every single day.

The Ultimate Job Site Breakdown: Finding Your Perfect Match

Let's look at the most common work environments and identify the must-have features for each. Find your job on this list to see what you should be looking for in your next pair of safety boots.

The Best Safety Boots for Tough Construction & Engineering Sites

Construction and engineering sites are among the most dangerous places for your feet. The hazards are everywhere, from the ground you walk on to the equipment moving around you. Using the wrong footwear here is not an option.

The Main Dangers on a Construction Site:

• Falling Objects: Heavy tools, bricks, and building materials can fall from heights.

• Sharp Objects: Nails, screws, rebar, and broken materials are all over the ground.

• Uneven and Rough Ground: Walking on dirt, gravel, and unfinished surfaces all day is tough on your feet and ankles.

• Wet and Muddy Conditions: Rain and site work can create slippery, muddy hazards.

Must-Have Features for Construction Footwear:

• Steel Toe Cap: This is non-negotiable. You need the maximum level of impact and compression protection. Our toe cap is designed for exactly this, offering 200 joules of impact resistance.

• Steel Midsole: A steel plate in the sole is essential to protect you from nails and other sharp objects. Our steel midsole provides a puncture-proof shield for the bottom of your foot.

• Durable Upper Material: You need a boot made from tough, genuine leather. It can withstand scrapes, cuts, and the general abuse of a construction site far better than synthetic materials.

• High Ankle Support: A mid-cut or high-cut boot provides extra support for your ankles, which is crucial when walking on uneven ground all day.

• Excellent Grip: A deep-tread, slip-resistant outsole is needed to keep you stable on mud, gravel, and wet surfaces. Our rubber or PU outsole is perfect for this.

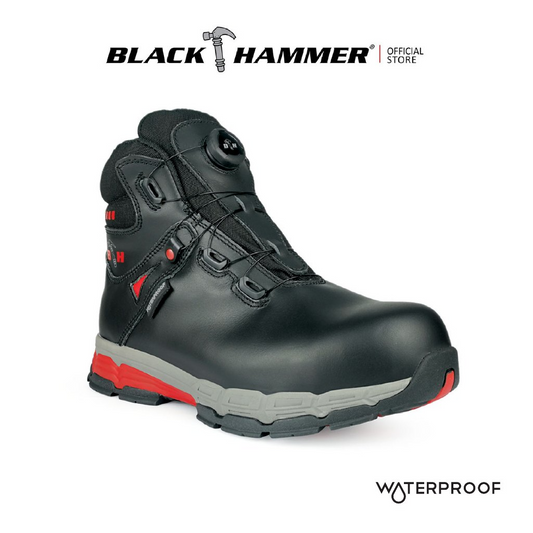

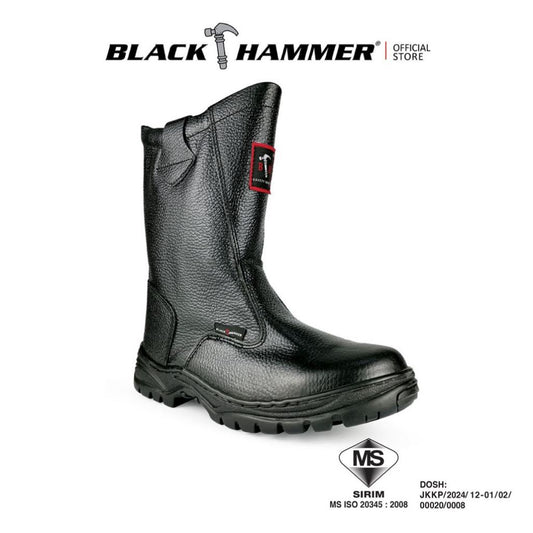

Our Recommendation:

If your boots are constantly failing on a tough job site, you are likely using a boot that isn't built for heavy-duty work. You need to upgrade. Our Black Hammer Heavy-Duty Collection is built specifically for the toughest environments. These boots feature all the essential protections to keep you safe and ensure your footwear lasts.

The Right Protective Footwear for Manufacturing & Factories

Factory floors can be just as hazardous as construction sites, but the dangers are often different. You're on your feet for long hours on hard, flat surfaces, often around heavy machinery.

The Main Dangers in a Factory:

• Hard Concrete Floors: Standing and walking on concrete for 8-12 hours a day causes extreme foot fatigue.

• Rolling Objects: Carts, forklifts, and heavy rolling equipment can crush your feet.

• Slippery Surfaces: Spills from oils, coolants, and other liquids can create slick spots.

• Repetitive Motion: Constant walking can lead to long-term foot problems without proper support.

Must-Have Features for Manufacturing Footwear:

• Excellent Cushioning: This is your number one priority. You need an insole with great shock absorption to fight foot fatigue. If your boot’s insole is flat, you should upgrade to an orthotic insole.

• Steel or Composite Toe Cap: Protection against rolling objects and dropped parts is essential. A composite toe is often lighter, which can help reduce fatigue over a long shift.

• Slip-Resistant Sole: Look for shoes with a certified slip-resistant sole to handle unexpected spills.

• Durable Construction: A strong bond between the upper and the sole, like our DuraStitch™ technique, is important to withstand the constant walking and movement.

Our Recommendation:

For factory work, a balance of protection and comfort is key. You need a boot that is tough but won't weigh you down. Black Hammer offers many models that are perfect for this environment, providing certified protection with all-day comfort.

The Most Efficient Work Boots for Warehouses & Logistics

In logistics, you are always on the move. You might walk many kilometers a day on a hard warehouse floor. Here, weight and flexibility are just as important as safety.

The Main Dangers in a Warehouse:

• Foot Fatigue: This is the biggest enemy. Heavy boots will drain your energy quickly.

• Falling Boxes: Dropped packages and boxes can cause foot injuries.

• Minor Bumps and Scrapes: Navigating tight aisles and pallet jacks can lead to bumps against your toes.

Must-Have Features for Logistics Footwear:

• Lightweight Design: This is the most important feature. A heavy boot is a huge disadvantage in this job.

• Composite Toe Cap: A composite toe provides certified protection but is much lighter than steel, making it the perfect choice for logistics.

• Flexible Midsole: A flexible Kevlar midsole offers puncture protection without making the shoe stiff, allowing your foot to move naturally.

• Breathable Upper: A mesh or combination upper allows your feet to breathe, keeping them cooler and more comfortable during a long, active day.

Our Recommendation:

Stop using heavy, old-fashioned steel toe boots for warehouse work. A modern, athletic-style safety shoe will change your workday. Our Lightweight Sport Series Collection is designed for exactly this. They feel more like trainers than work boots, offering the perfect blend of agility and certified protection.

The Safest Shoes for Kitchens, Hospitality & Wet Environments

In kitchens and hospitality, the biggest danger is clear: the floor. Water, grease, and food spills create extremely slippery surfaces where a fall can be disastrous.

The Main Dangers in a Kitchen:

• Slippery Floors: This is the number one hazard.

• Hot Liquids: Spills of hot oil or water can cause serious burns.

• Dropped Knives or Equipment: Sharp or heavy objects can fall on your feet.

Must-Have Features for Kitchen Footwear:

• Superior Slip-Resistant Outsole: This is the most critical feature. You need a sole specifically designed for wet and oily surfaces.

• Water-Resistant Upper: A leather or non-mesh upper will protect your feet from hot liquid spills.

• Protective Toe Cap: A steel or composite toe protects you from dropped items.

• Easy to Clean: A smooth, non-fabric upper is much easier to wipe clean at the end of a shift.

Our Recommendation:

Not all slip-resistant shoes are created equal. For the extreme conditions of a commercial kitchen, you need a specialized solution. Our SafeX brand is engineered specifically for wet and slippery environments, offering the best possible grip to keep you safe on your feet.

A Deep Dive into Safety Shoe Features

Understanding the parts of a safety shoe helps you choose the right one. Let's break down the key technologies and materials.

Understanding Toe Protection: Steel Toe vs. Composite Toe

• Steel Toe Caps: Think of these as a metal shield for your toes. They offer the maximum possible protection against impact and crushing. They are the best choice for heavy-duty environments like construction. All our steel toes are certified to meet international safety standards.

• Composite Toe Caps: These are made from non-metal materials like carbon fiber, plastic, or Kevlar. They provide certified impact protection but are much lighter than steel. They are also great for electricians as they don't conduct electricity. They are the perfect choice for logistics, light manufacturing, and any job where you walk a lot.

Understanding Midsole Protection: Steel Plate vs. Kevlar

• Steel Plate Midsoles: A thin steel plate is placed in the sole to stop nails and other sharp objects from puncturing through to your foot. This is a must-have for construction and demolition sites.

• Kevlar Midsoles: This is a modern, fabric-based plate that is just as puncture-proof as steel but is incredibly flexible and lightweight. It allows the shoe to bend and move with your foot, making it much more comfortable for active jobs.

Understanding Upper Materials

• Genuine Leather: This is the king of durability. It’s tough, breathable, and can withstand a lot of abuse. It's the best choice for rugged outdoor and industrial jobs.

• Mesh & Synthetic: These materials are used to make shoes more breathable and lightweight. They are perfect for indoor jobs where you are very active and your feet get hot, like in a warehouse.

• KPU (Kevlar Polyurethane): This is a modern material that is often combined with leather or mesh. It provides extra durability and support in a lightweight package, perfect for our Sport Series shoes.

How to Choose Your Perfect Boot in 3 Simple Steps

Feeling overwhelmed? Don’t be. Just follow these three simple steps.

Step 1: List the Top 3 Dangers of Your Job

Be honest about what you face every day. Is it falling objects? Slippery floors? Walking 10 kilometers? Write them down.

Step 2: Match the Dangers to the Features

Use the guide above to match your list of dangers to the must-have features.

• Danger of falling objects? You need a steel toe.

• Danger of slippery floors? You need a slip-resistant sole.

• Danger of walking all day? You need a lightweight composite toe and good cushioning.

Step 3: Find the Boot That Has Your Features

Use the navigation on our website to filter for the features you need. This will narrow down your options to only the boots that are the perfect tool for your job.

Conclusion: Invest in the Right Tool, Protect Your Feet

Choosing the right safety boots for the job isn't just about buying a new pair of shoes; it's about investing in the right tool for your daily safety and comfort. Using the wrong boot is a waste of money and a risk to your health.

By understanding the real demands of your job and matching them to the specific features of your footwear, you can buy with confidence. You'll get a pair of work boots that not only protect you from injury but also last longer, feel more comfortable, and provide real value for your hard-earned money.

Ready to find the perfect tool for your job?